- cross-posted to:

- knives@lemmy.world

- pocketknife@lemmy.world

- cross-posted to:

- knives@lemmy.world

- pocketknife@lemmy.world

cross-posted from: https://lemmy.world/post/9160400

cross-posted from: https://lemmy.world/post/9035683

And you’ll never guess what kind of knife it is. Go on.

…

Yes, of course it’s a balisong box cutter. Because it just is.

Update: And the .STL files are released! Get them here, along with assembly instructions, and other sundry bumf.

Okay, so it’s not exactly an exciting custom collaboration with a big name manufacturer made out of a supersteel with rich exotic handle materials in a fancy matte box. That would require being considerably more involved with the industry than I am. Which is not at all.

Rather, this is a 3D printable utility/fiddle toy that’s

ripped off fromjust a smidge inspired by the Gerber EAB we were talking about the other day. Why doesn’t anyone make a flipper like that?So as our resident balisong expert, I just had to ask myself the other day just how hard developing a working balisong knife could be.

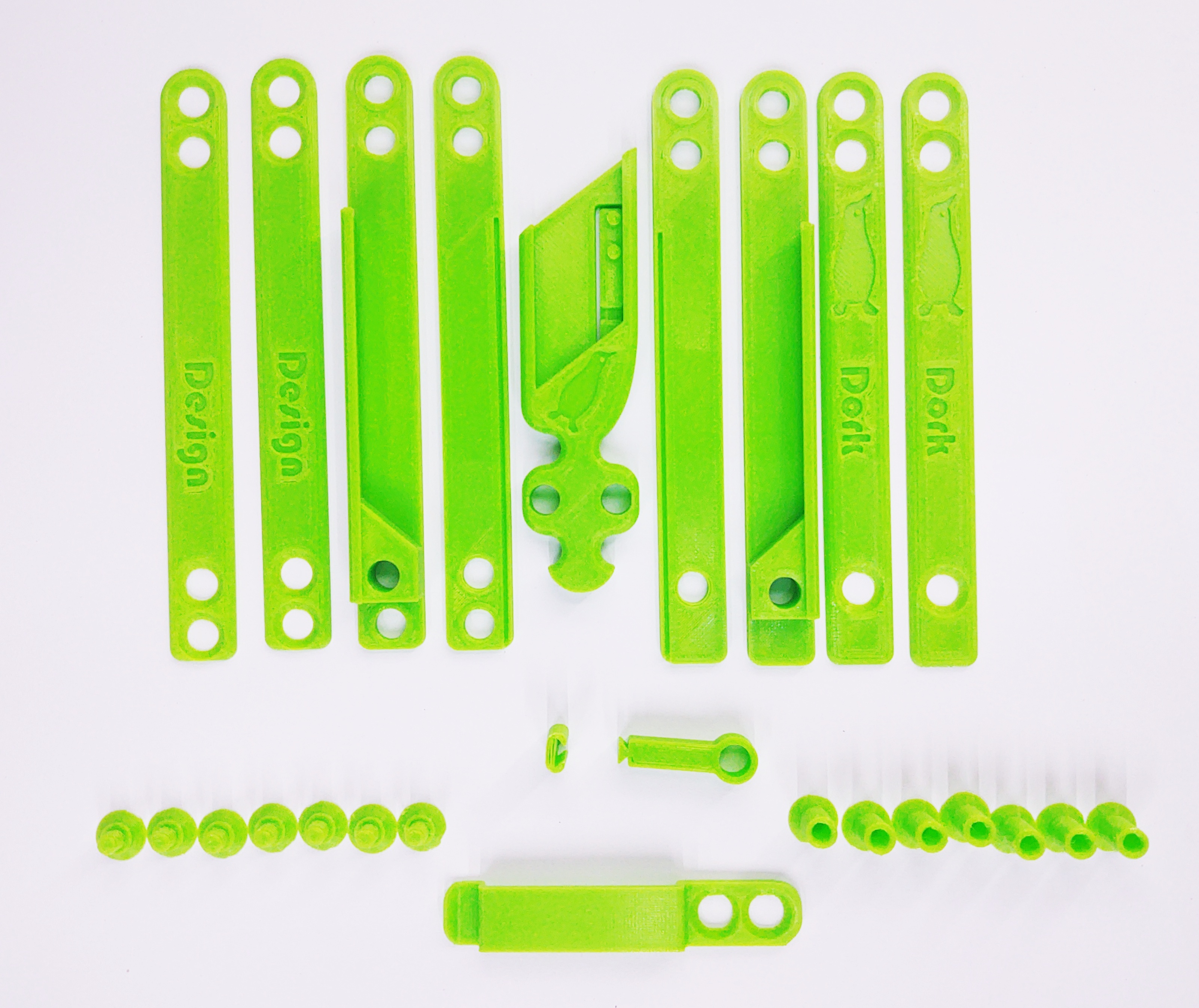

The answer is more than you’d think at first blush. I’m not at all ashamed to report that the production and assembly of one of these takes no less than 26 individual components if you include…

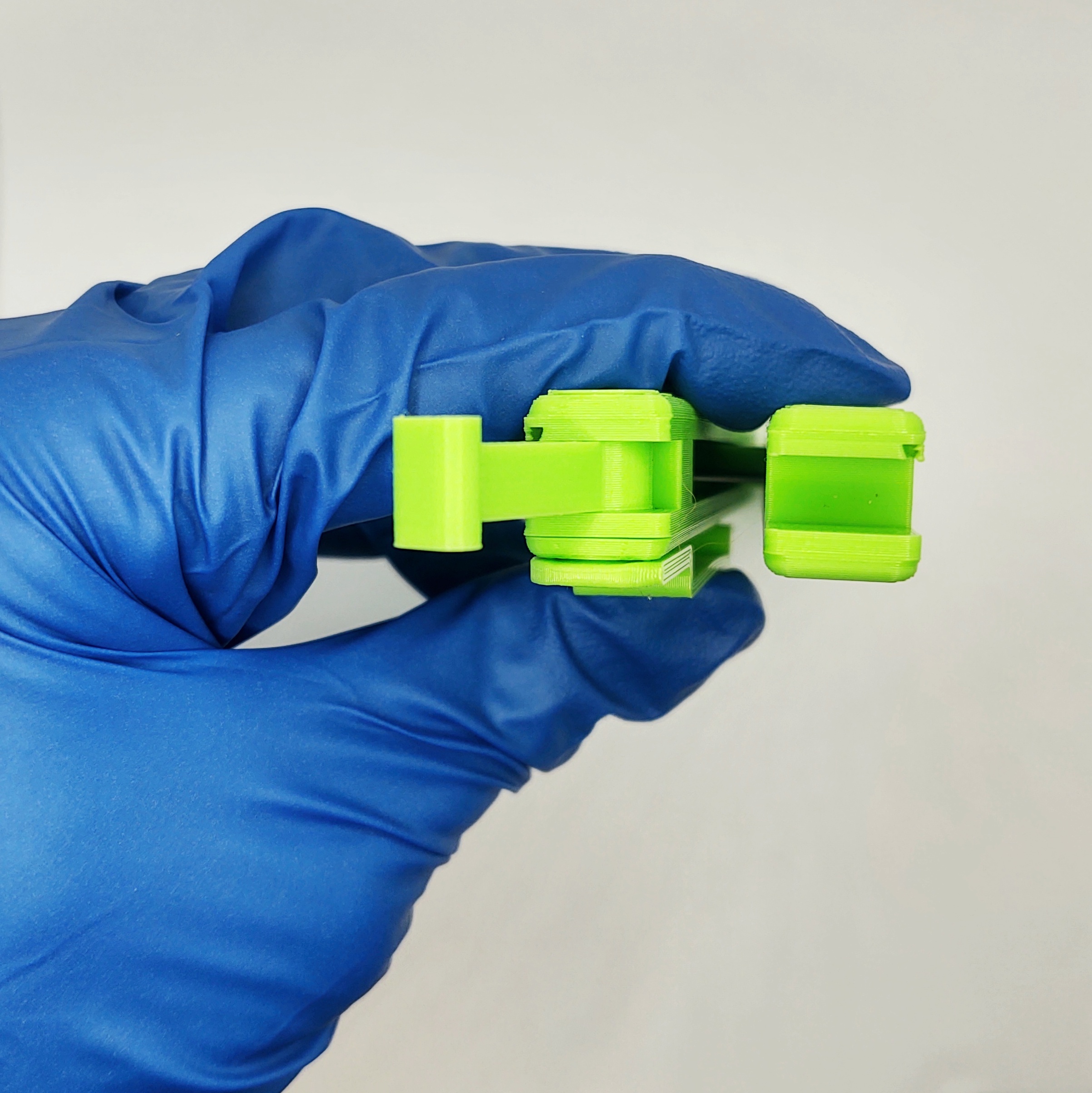

…The optional but fully functional pocket clip.

And yes, it even has a fancy kickerless design with “zen” pins like your big dollar brand name balisong model.

“But does it actually work?” I hear you cry.

You’re damn skippy it does.

My design goals were: 1) Make a functional balisong knife that 2) is completely 3D printable without reliance on outside hardware – other than the blade, obviously – that 3) plays to the strengths and avoids as much as possible the weaknesses of filament deposition printing and 4) does not require using any supports.

(And yes, you could print the blade, too. If you wanted it to be laughably ineffective.)

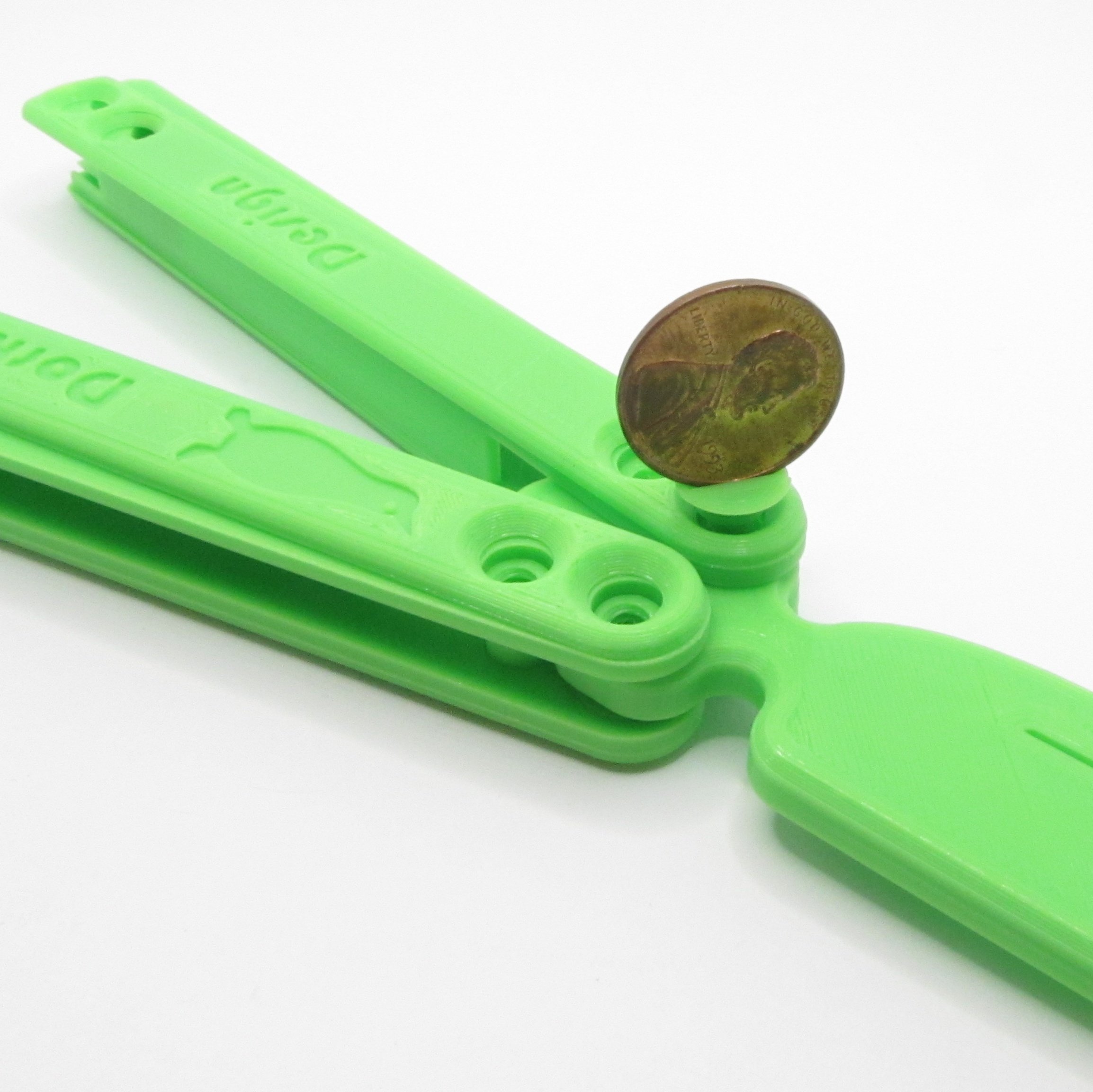

Even the assembly hardware is 3D printed, and you can install it using nothing but a penny.

I know you all have been holding your breath until I posted this picture. There you go. You can breathe out now.

Oh, and also: Would you like to use this as a fidget toy that won’t get you in too much trouble in polite company, or at the office, or in some backwater hellhole where balisong knives are illegal?

You’re in luck. Because there’s a blunt trainer blade for it, too.

The Burning Questions I Know You’re Going To Ask:

Q: What are the sizes and weights?

42.1 grams. 1.48 ounces. This thing is the second lightest balisong knife I currently own. I designed it in metric, but in keeping with tradition around here it is almost exactly 5" long when closed, 7-1/2" long open (with a typical Stanley style blade installed), 1-1/8" of usable blade edge, and 5/8" of an inch thick (not including the pocket clip, which you can leave off).

Q: That’s very funny, but the tolerances on this plastic piece of shit are terrible, right? What does the wiggle test look like, smart guy?

Bam. Stick that in your pipe and smoke it.

Q: But, it’s made out of plastic. Isn’t it going to break or erode into nothing, like, instantly?

I’ve been messing around with the above pictured example for about a week now and I’ve probably flipped it somewhere between six thousand and a zillion times by now. I’ve been using it to cut up boxes at work all week, too. It’s as perfect as the day I minted it.

Q: Isn’t cold creep in the PLA going to turn it into a banana eventually?

Maybe! Probably! We’re sure as hell going to find out.

Q: Are you going to sell these or something?

I’m not ruling it out, but that wasn’t my goal here. I might give a couple away at some point, though.

Q: Then can you shut up and give us the fucking STL files already?

Soon. In order to prevent this post from being longer than it already is, I’m going to release the files and assembly instructions separately. After I’m good and satisfied the design is well tuned enough to inflict upon the unwashed masses, anyway.