This post is a follow up to this post here Quality issues where I was having tolerance problems with lead me to discover inconsistent extrusion in base mode.

It has been quite a ride and I used a lot of the suggestions given in the last thread, and also discovered several other problems which lead to a major rebuild/redesign of the corexy x and y axis, bed motion, and extruder. Here is what I found:

The first thing I noticed were the shafts in the x/y stepper motors appears to be bent just slightly. If I watched the pulley on the motor it appeared to wobble. I replaced both motors with some spares I had laying around from various projects. The x and y gantries both move on linear rails, and I ended up totally reprinting the carriage adapters as well.

Second, I had 4 points leveling on the bed, which I know is quite controversial. I found that the z screw coupler in one corner has become stretched out and wasn’t really adjusting height correctly when I ran my 4 point script. I modified the bed so two steppers are connected in series and moved the pivot point between the 2 old pivot points. The bed moves on 4 linear rails and 4 smooth rods with z-screws between the rod and the rail. I got rid of the spring type couplers and replaced them with solid couplers. Any wobble in the screw is taken up by wobble nuts.

Third, and probably most important, I realized the zesty nimble 2 extruder was suffering plastic fatigue. If your not familiar, the zesty nimble is 85%-90% sintered nylon. There is one hobbed gear and a “breech” that holds the filament against the gear. The breech clips onto ears on the main body of the nimble. One of the ears, over time, has gotten a bit weak and the breach only consistently clips into one side causing less pressure to be put on the filament against the extension mechanism. I could have inverted the mount, reprinted it, and flipped the nimble as you can use it either left handed or right handed, and bought some time, but zestytech has gone out of business, so I decided it was time for a change. I picked up a shiny new orbiter 2.5, and printed a new hot end carriage, a hero me, and totally rebuild the print head.

I spent a couple of hours updating and doing basic tuning on the config and am much happier with the results. I still need some more tuning, need to work on wire management, and come up with a better wire support instead of the old number direct drive cable. I may eventually reuse the number as a second print head extruder but that is a ways off.

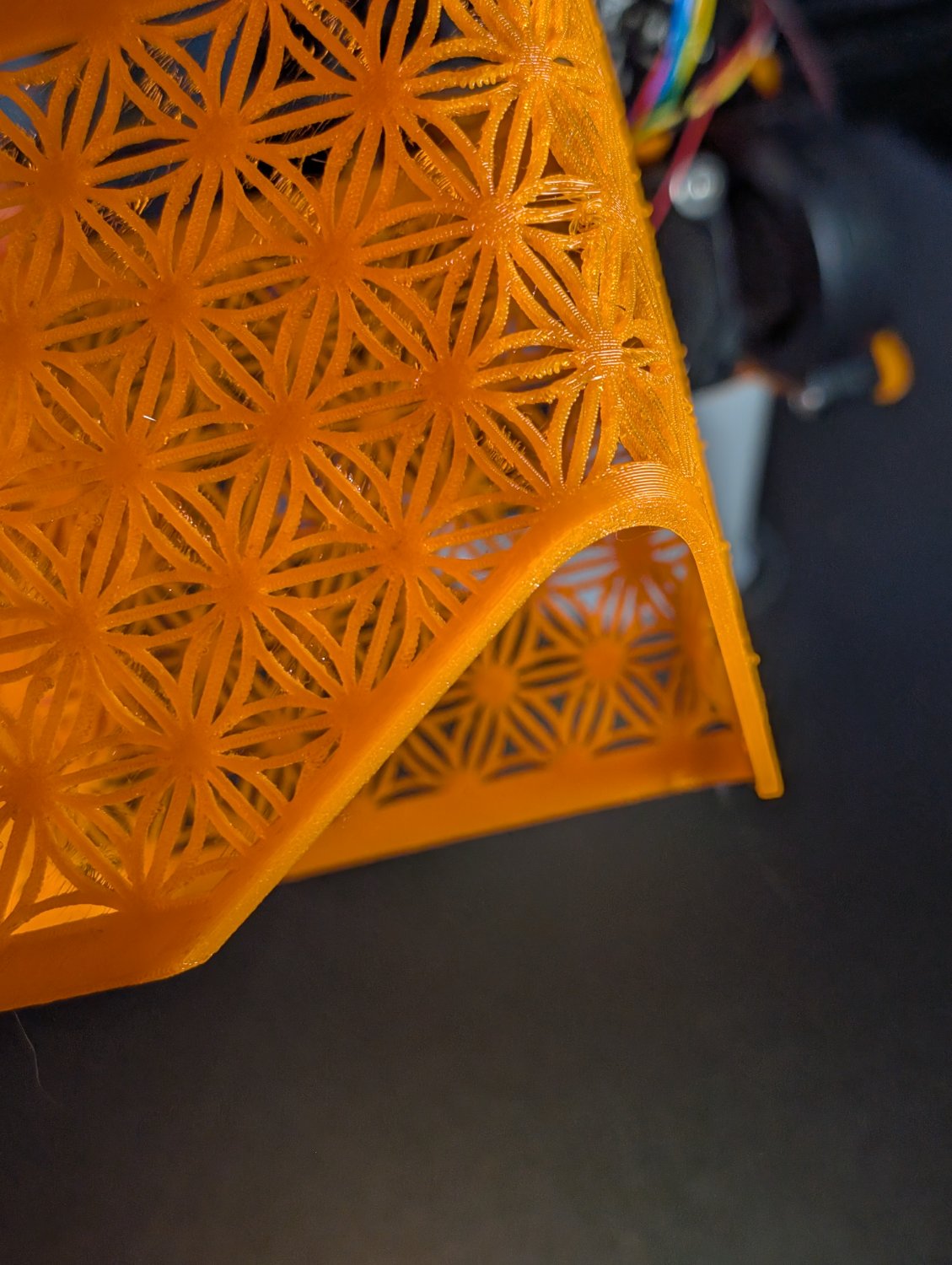

Here are some of my first prints from the new setup.

I still need a bunch more tuning: extruder stepper vref tuning, retraction, print temperature, feedrate, etc, but I feel like I am finally getting somewhere.

The lack of banding and wobble is excellent, especially compared to where you came from. You’ve got me thinking about a new extruder. I’ve got some no name aluminum extruder setup right now, but I’ve put enough abrasive filament through that it’s made all my filament paths oblong.

Nice work!

I really like the orbiter 2.5. it’s not as light as the nimble but it is still tiny. I like that it is open source and they really have thought to put a bunch of engineering in to the gear workings instead of just using clone bonditech gears. It cost, like, 48 USD to get from AliExpress and is definitely high quality.

Thh Hero Me mount seamed like a good choice as well. It was a huge pain in the a$$ to assemble tho, not that I am complaining. The way it mounts to the carriage means you can’t just assemble and mount (at least with my old tronxy carriage plate). The included adapter design that comes in the file package didn’t quite work correctly and I didn’t realize that until I was all disassembled. There is a magnet mount version that would probably have been a better option. I’ll probably print one to have as a spare if I ever need to disassemble the mount. Other then the mounting tho I really like the design and thought that went into it by mediaman.

I did print myself a herome mount and everything awhile back. Added dual fans and whatnot, I was having a terrible time with petg surface quality, the dual fans helped a lot. I also had to reassemble my hotend to reprint something I messed up lol.

I’m at the point now where I’ve replaced so much on my ender that it doesn’t really look like the machine I bought, except that it’s still i3.

I’ll check out the orbiter, thanks!