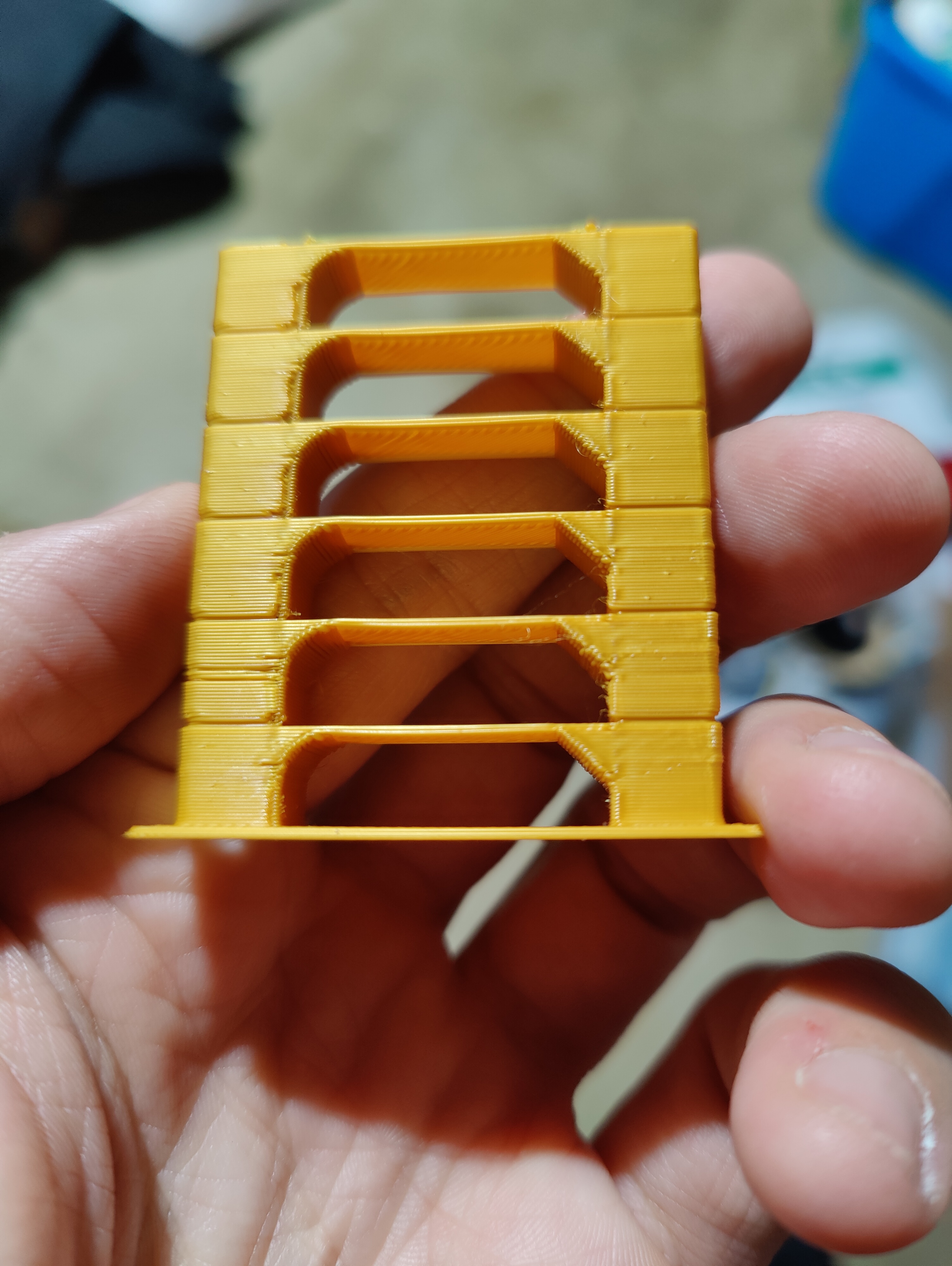

To be clear I know it’s not well lol. I just wanted the community’s thoughts on what I’m doing wrong. I’m using Overture Royal Gold on a modified CR-10v2 with a real V6. Model was sliced in cura with default low quality settings.

The filament I bought a few months ago but just broke it open yesterday. It’s making some small popping noises every now and again but the seal didn’t appear to be broken. It seems all right otherwise, if a little sticky on the roll. I had to move it out of my filament dryer to keep it from opening the lid because it was binding so much. That’s what happened to the last tower, that failed mid print. Looks nice at least.

It’s a bit hard to tell from that photo, but just generally I’ve found this to be an excellent resource for diagnosing print quality issues and potential solutions:

https://help.prusa3d.com/category/print-quality-troubleshooting_225

In particular for this print, you might find the “Layer separation and splitting FDM” and “Layer shifting” sections helpful

Ooh this is exactly what I’ve been looking for, thank you!

It’s managed to get beyond 200C this time! But it did fail at 190°, though that’s the low end of the temp range anyway.

Back looks… Okay. I’m assuming that’s the Z-seam on the inside of the arch. Bridging looks best on 220°, and I don’t know what the deal with that line in the middle of 215° is, best guess is under extrusion by way of friction but idk. It broke apart right where it thins out between 205° and 200° too, so that might be my lower bound.

Even if it looks well sealed, it still could be humidity and popping sound usually means wet filament. That being said, you didn’t mentioned if it was pla/petg… Guessing it is pla due to the temp you are using but always best to mention it. Have you watched the print ? Did it actually change temp while printing? because between 190 and 220, there is usually more difference than what you have here, especially on the bridge part.

It did! And it is pla. It did change, I used kartchnb’s auto tower addon. The bridging looks pretty good on the first few sections but the layers didn’t bind on the upper sections. Honestly 220 looks the smoothest for that and the overhangs.

PLA can tolerate quite huge range od tems. Thats why this test is not best IMO. I found better to print single wall cube with no bottom and no top (also changing temp every 5 mm of height). That way you can see how it looks, but you can also test layer bond by breaking the part with fingers. It is also much faster print.

Just my 0.02

I agree with this, PLA is the most popular material for a reason. It’s pretty easy to get good results without a lot of tuning.

Temp towers are a huge help with PETG though which has much more trouble with sagging overhangs and stringing. It took me a bit of practice to get results I was happy with for PETG.

Be sure to apply that script to actually change the temperature. There is not really a change visible. Also the extrusion stops when printing the digits. That’s weird.

It did actually change the temp! It’s the auto tower addon for cura, all I had to do was select the model and hit print. Plesantly surprised, last time I made one it was a bit of a slog.

Also yes it’s very weird, I’ve no clue why.